The V807 not only can "do everything" as a standalone unit, but it can also be part of a larger fully-automated production line that connects to other Voortman machine to increase throughput, capacity, and production. Voortman robotic stainless steel processing machines provide the highest throughput and production, thanks to fully-automatic material management at the infeed or outfeed. Automated cross transports, as well as roller conveyors, can quickly get the next sections ready for processing while you are cutting the current piece.

Voortman CNC Beam Cambering has a rigid-steel frame, horizontal piston pusher and memory settings. It also provides reliable output for all types of projects. The touchscreen operator panel makes it easy to control the V2000.

Cost efficient thermal and plasma robotic profiling machine

Robotic Coping, Profiling can make your fabrication process more efficient. This robot is designed to work with angle lines and beam drill lines. This is a great way to improve your fabrication processes by taking them from zero to one hundred.

What are the possibilities for the coping process? You can see this video to learn about the benefits of having a robotic profile processor from Voortman customers.

Voortman CNC Beam Cambering uses a rigid steel C frame, horizontal cylinder pusher, and memory settings to ensure reliable output for every project. The touchscreen operator panel makes it easy to operate the V2000. Voortman V2000 beam cambering and straightening machine produces consistent, reliable output every single time.

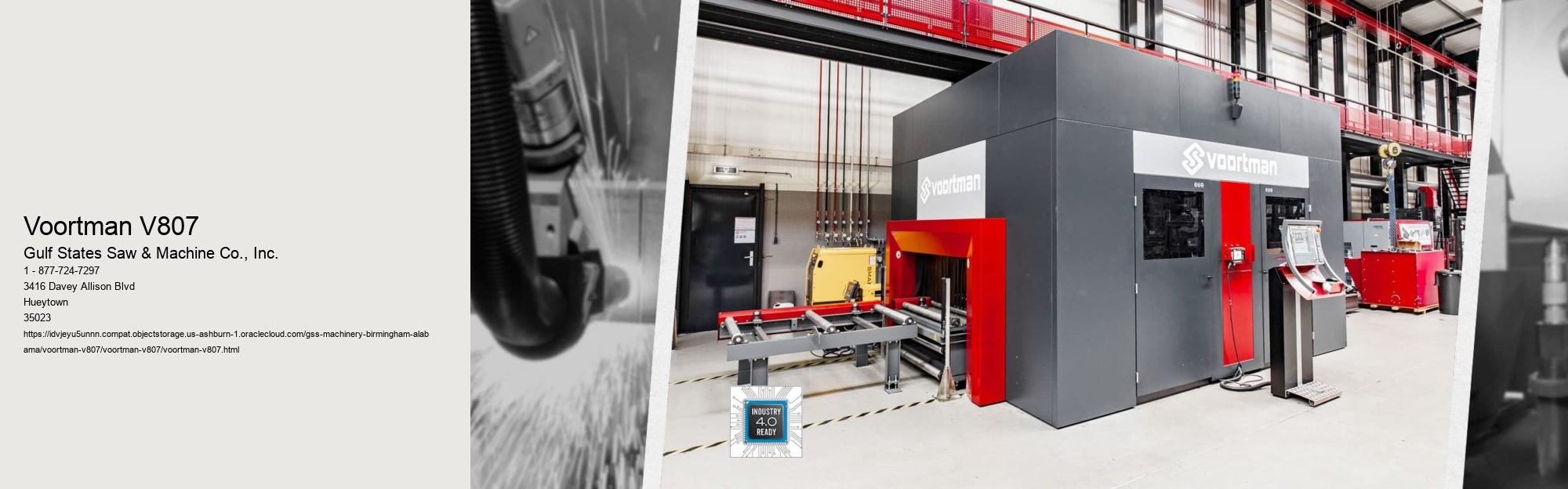

Voortman V807

For those who may have questions as to the standards of our Robotic coping and profiling machine, we can confidently say that ours has scaled the most vital fabrication tests successfully; hardness, surface texture, beam flange weld access hole quality, bolt hole sizing, positioning and perpendicularity. As always, we have through our stocking made available the Voortman CNC coping and profiling machine, which is designed to an exceptional standard just for you, hence its outstanding capacities.

Gulf States Saw & Machine Co. uses a Cframe of steel, horizontal pusher, and memory settings to produce Voortman CNC Beam Cambering. All projects are guaranteed reliable output thanks to this system. Voortman CNC Beam Cambering comes with a touchscreen operator board, making it easy to use V2000.

Gulf States Saw & Machine Co. is confident that its Robotic Coping and Profiling technology is unmatched in the industry. This plasma technology system can be used to cut through a wide range metal profiles.

Voortman CNC Beamcambering comes with a rigid steel frame, horizontal piston pushinger, and memory settings. It delivers reliable output for all projects. The V2000's touchscreen operator panel allows for easy control.

Because we are particular about making fabrication tasks seamless and efficient, we have here this Robotic coping and profiling beam that is designed to process angle bars, channels, square tubes, but als pipes, T Bars, plates and bulbs as well. With any of our Coping and profiling Robot, the possibilities of functions on your profiles/pipe cuts are truly limitless as it is an efficient tooling system unmatched in terms of the quality of its outputs. These outputs can be H, I and T beams, U and L channels respectively.

Voortman CNC Beam Cameraring has a rigid-steel framework, horizontal piston pusher, and memory settings. It can also provide reliable output for all kinds of projects. It is easy to use the touchscreen operator panel to control V2000.

Voortman CNC Cambering uses a rigid steel Cframe and a horizontal Cylinder Pusher. It also has memory settings. Each project receives a reliable output. It is easy to use because the V2000's touchscreen operator panel makes it easy to operate.

Voortman CNC Beam cambering features a rigid-steel frame and a horizontal piston pusher. It also has memory settings. It provides reliable output for all types projects. The V2000 can be controlled via touchscreen from the operator panel.

Problem-based coping is one type of coping skill. Emotion-based coping is another. Knowing the differences between them can help you choose the right coping strategy.

A coping is an architectural addition that covers bricks and protects them from the elements. It rests on top of a wall, and extends down to its edges.

There are two types of steel beam connections: seated and framed.

There are four main categories of coping: [1] Problem-focused, which focuses on the cause of distress. Examples include active coping and planning. Restraint coping is the suppression of competing activities.