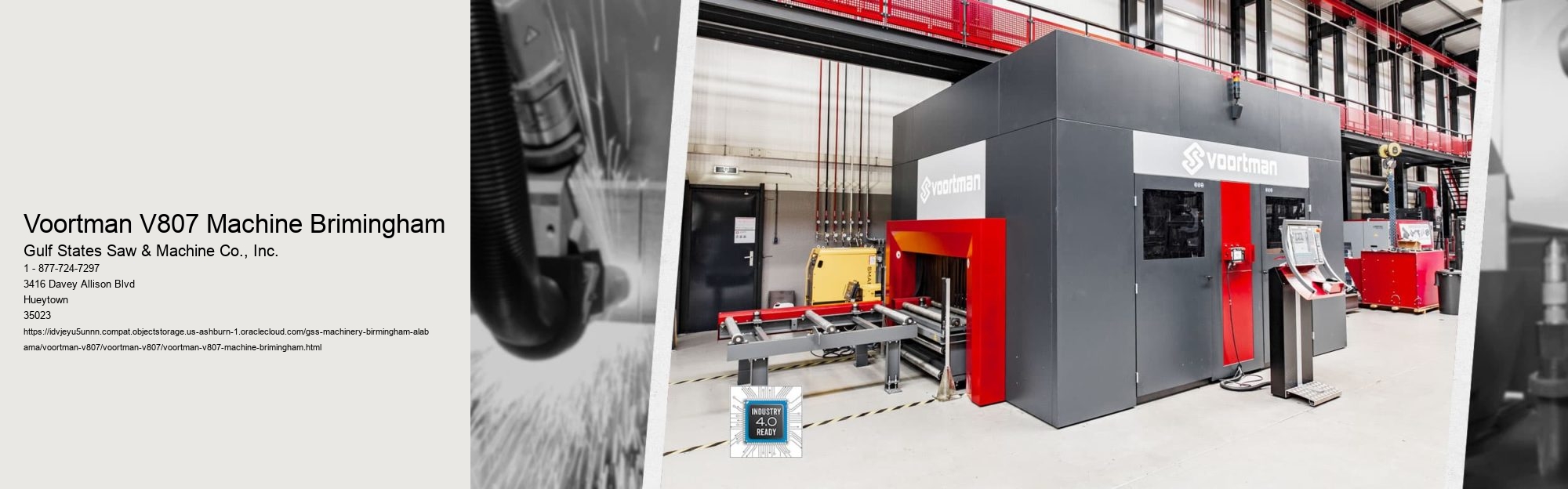

Voortman V807 robotic thermo profile cutting system is capable of processing all types of material, including copes, bolt holes and slots. It can also be used to prepare and mark welds and make layout markings. The V807 offers a significant economic advantage over traditional drilling, milling or sawing systems. This combination of these functions in one machine allows for faster ROI and less floor space.

The Voortman CNC Beam Cambering utilizes a rigid steel C-frame, horizontal cylinder pusher and memory settings for a reliable output with every project. It contains a user-friendly touchscreen operator panel that makes operating the V2000 easy. Our Voortman V2000 Beam Cambering & Straightening Machine are Repeatable, reliable output every time.

Voortman CNC Cambering utilizes a Cframe made of rigid steel and a Cylinder Pusher. It also features memory settings. Each project receives a reliable result. It is simple to use the V2000's touchscreen operator panels.

Voortman V2000 Beam Cambering & Straightening Machine

BENEFITS INCLUDE: Smart Cambering, Accurate and Automated Positioning, Hydraulic cylinder pusher, PLC Control, Remote Control for Mobility, Combination cambering with Voortman machines

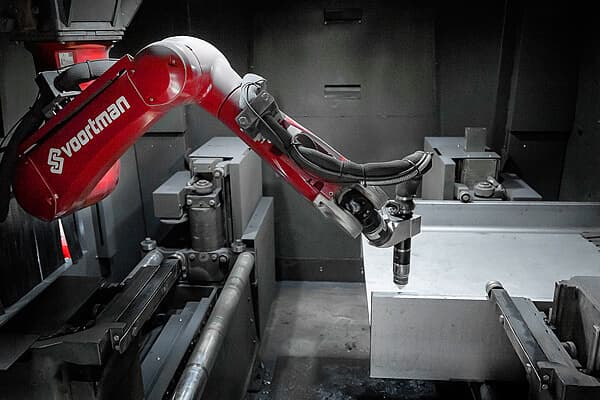

Our top-of-the-range coping/profiler robot makes 3D coping and profiling much easier. These Robotic Coping and Profile beams are reliable and can be used to cut slots, chamlers, and saddles.

Voortman CNC Cambering features a rigid steel Cframe and a horizontal Cylinder Pusher. It also has memory settings. This guarantees reliable output for every project. The touchscreen operator panel makes it easy to control the V2000.

Voortman CNC Beam Cambering has an all-steel frame, horizontal piston pusher, and memory settings. This guarantees reliable output for all of your projects. The touchscreen operator panel makes it easy to use the V2000.

The V807 provides a quicker return on investment with cost savings over separate solutions for drilling, milling, sawing, punching, shearing and marking. All processes can be handled easily in one pass with the V807, and its revolutionary rotational axis ensures maximum reachability and versatility for minimal manual intervention - load raw profiles and unload finished products!

Robotic Coping or Profiling is equivalent to an automated, optimized fabrication process. This system can operate the following processes: angle lines, beam drilllines, hydraulic punches. Ironworkers, bandsaws, coping machines, and band saws. This is an easy way to transform your fabrication processes into a hundred.

Give us the opportunity to help you choose the most appropriate, cost-effective manufacturing equipment for your requirements.

We can assure you that the Robotic coping/profiler machine has passed all critical fabrication tests: hardness, surface texture and beam flange access hole quality. It also successfully scaled bolt hole sizing and positioning. We have made available, through our stocking, the Voortman CNC Coping and Profiling machine. It is designed to an extraordinary standard for you, hence its exceptional capacities.

We pride ourselves on making fabrication tasks as seamless and efficient as possible. Therefore, we offer this Robotic coping/profile beam. It is capable of processing both square tubes and channels, but also pipes, T bars and plates. Our Coping and profiling robots can perform a wide variety of functions on your pipe cuts/profiles. They are an extremely efficient tooling system, which is unmatched in terms quality. These outputs may be H, T beams, U or L channels.

Gulf States Saw & Machine Co. uses a rigid and steel C frame with a horizontal pusher and memory settings when producing Voortman CBN Cambering. This ensures consistent output for all projects. Voortman CNC Beam Cambering is equipped with a touchscreen operator panel. It's easy to use.

Coping is a process that allows a beam to fit into other parts of a framework.

Coping refers to the covering of a wall. You can use stone, tile or concrete to cover a wall. Flashing, on the other side, involves the installation of impermeable materials such as copper or lead to prevent water from entering the structure.

The twice-weathered coping stones are shaped in an inverted V shape. This allows water to flow off the walls from both sides.

The concrete is usually caulked or filled using elastomeric sealant at the expansion joint between the deck and the coping approximately 30 days after it was poured. This allows concrete to settle and take on its permanent structure. It may not align correctly if it has been caulked prior to this time.