Voortman CNCBeam Cambering comes with a rigid steel Cframe as well as a horizontal Cylinder Puller and memory settings. This ensures reliable output for all projects. It also features a touchscreen operator panel which makes controlling V2000 extremely easy.

Voortman CNC Cambering uses an aluminum C frame and a horizontal cylinder pusher. It also has memory settings that ensure reliable output. The V2000 can be operated via touchscreen from the operator panel.

Gulf States Saw & Machine Co. employs a rigid, steel C-frame, horizontal pusher, and memory settingsin their production of Voortman CNC Beam Cambering. This ensures reliable output with all projects. Voortman CNC Beam Cambering features a touchscreen operator panel with easy-to-use functionality that makes using the V2000 simple.

Voortman V2000 Beam Cambering & Straightening Machine

Voortman CNC Cambering employs a rigid steel frame, horizontal cylinder pusher and memory settings for reliable output. The V2000 is easily operated by the touchscreen operator panel.

Voortman CNC Beam Cameroning features a Cframe made of rigid steel, a horizontal Cylinder Pusher, and memory settings. You get a reliable result with every project. It's easy to use the touchscreen operator panel on the V2000.

Gulf States Saw & Machine Co. can assure you that your Robotic Coping and Profiling system is the best in the industry. It uses high-definition plasma technology to cut through a variety of metal profiles, including structural steel and other metal parts.

Because we care about making fabrication tasks simple and efficient, this Robotic Coping and Profiling beam is available. It can be used to cut angles, channels, square tubes and plates as well as pipes, T bars, plates, and bulbs. You can do anything you want with our Coping and Profiling Robots. The quality of the outputs is unmatched. These outputs can include H, I andT beams, U, and L channels, respectively.

Expect a consistent, reliable result each time.

Voortman CNC Beam Cambering features an All-Steel C frame and horizontal piston pusher. There are also memory settings. This ensures that you get reliable output for your projects. It comes with a touchscreen operator panel which makes it simple to operate V2000.

BENEFITS: PLC control, remote control for mobility, Smart cambering.

Voortman CNC Cambering uses both a rigid steel frame and a horizontal Cylinder Pusher. You can also set memory settings. Every project gets a reliable output. The touchscreen operator panel on the V2000 makes it simple to use.

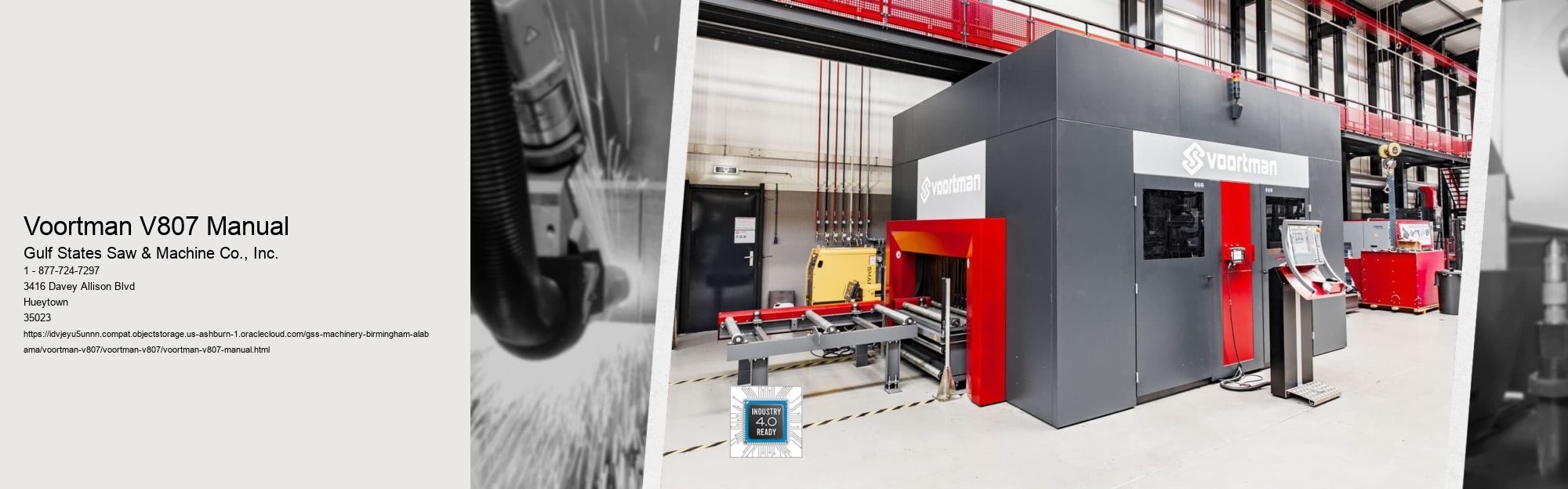

Voortman Stahl Machinery is proud announces the VoortmanV807 robotic temperature profile processing machine. It can plasma or oxy-fuel cut with more throughput that any other robotic profile processors on the market. After the highly successful V808 profil processor, the V807 was developed through years of experience, research, and development. This machine has a reduced footprint and an enhanced capability and performance.

Cope and Drag are the top and bottom of Sand Casting molds. These are metal flasks that contain and support the Green Sand during mold making and mold pouring.

Cope and drag patterns allow two mold parts to be made separately and then assemble together. Useful for casting heavy, difficult to handle parts.

According to AWS, there are five types of welding joints that are commonly used in the industry: Tee joint welding. Tee joint welding. Corner joint welding Lap joint welding. Edge joint welding

Coping, also known as scribing, is a woodworking technique that shapes the end of a frame or moulding component to fit the contours and lines of an abutting part. A cope is used to join tubular metalworking members. It can also be called a "fish-mouth joint", or a saddle joint.