Voortman V2000 Beam Cambering & Straightening Machine

Gulf States Saw & Machine Co. uses a Cframe and horizontal pusher made from steel as well memory settings for Voortman CNC Beam Cambering. This guarantees reliable output for all projects. Voortman CNC Beam Cambering is equipped with a touch-screen operator panel. It makes it easy and intuitive to use V2000.

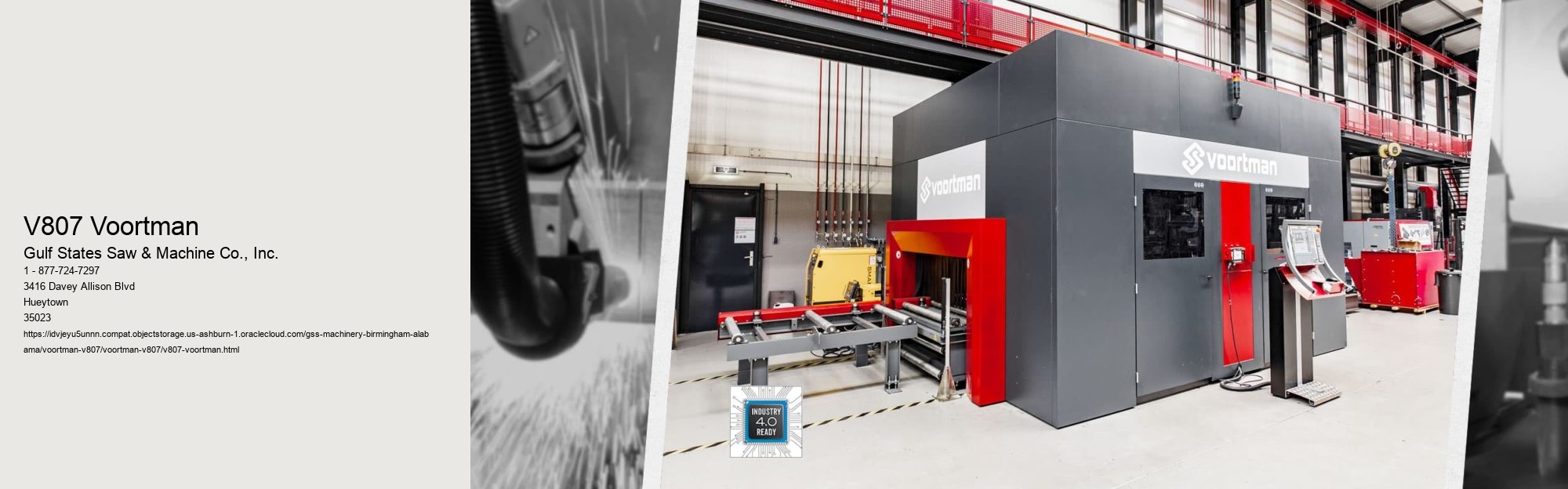

V807 VoortmanEvery time, you can expect a consistent and reliable result.

Voortman CNC Cambering uses an aluminum Cframe and a horizontal Cylinder pusher. It also comes with memory settings. Each project receives a reliable outcome. The V2000's touchscreen operator panel makes the process easy.

Voortman V2000 Beam Cambering & Straightening Machine

You can be sure of a reliable and consistent result every time.

BENEFITS INCLUDE: Smart cambering, Accurate, automated positioning, Hydraulic cylinder with pusher, PLC control, Remote control for mobility, Combine cambering with other Voortman machines

Voortman CNC Beam Cambering has a rigid steel Cframe, horizontal Cylinder Pusher and memory settings. This ensures reliable output on every project. It has a touchscreen operator panel, which makes controlling the V2000 very easy.

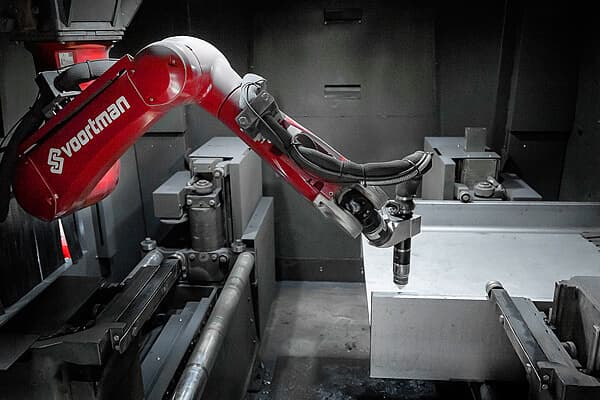

Thermo- or Plasma robotic profiling machines that are cost efficient

Voortman CNC Cambering employs a rigid, steel Cframe and horizontal Cylinder Pusher. It has memory settings. Each project receives reliable output. It's easy to use, thanks to the V2000 touchscreen operator panel.

Voortman CNC Beam Cambering has a rigid-steel frame, horizontal piston pusher and memory settings. It also provides reliable output for all types of projects. The touchscreen operator panel makes it easy to control the V2000.

We are very particular about making fabrication tasks easy and efficient. This Robotic coping beam and profiling beam can process square tubes, angles bars, channels, square pipes, as well as T bars, plates, bulbs, and other materials. The possibilities for functions on your pipes/profiles are endless with any of our Coping or profiling Robots. It is an extremely efficient tooling system that produces high quality outputs. These outputs could be H, I, and T beams respectively, or U and L channels.

Gulf States Saw & Machine Co. has the assurance that their Robotic Coping and Profiling systems are second to none. They have a high definition plasma technology system that can cut through a wide variety of metal profiles.

Voortman CNC Cambering uses a rigid steel Cframe and a horizontal Cylinder Pusher. It also has memory settings. Each project receives a reliable output. It is easy to use because the V2000's touchscreen operator panel makes it easy to operate.

Coping is used to perform balance or sliding tricks. It is important to make sure that the pipe is made of very thick, tough steel (schedule 40 non galvanised steel pipe), so it does not easily become dented.

Coped Joints Coping wood joinery technique ensures professional-looking results. This is especially true for moulding patterns that have a higher degree of detail and rooms with irregular corners.

Design basics for pipe stress. Keep pipe stresses below their code-allowed limits in order to prevent damage. Limit forces at the pipe-equipment connections to the recommended limits set by the equipment manufacturer. Large displacements should not cause low spots or cause the pipe to collide nearby objects.

Structural Fab Machinery, Fabrication Machinery. To describe the process of cutting reliefs in parts so that they can be properly fitted, we use the common term "Coping" in the metalworking industry.